CNC (Computer Numerical Control) Machining has applications in every manufacturing industry. Manufacturers are always looking for new innovative techniques in CNC machining, that can elevate their production and reduce their costs.

What is CNC machining?

CNC machining is a process of manufacturing parts through the use of machine tools. These machines automate the industrial manufacturing processes. They run on an algorithm written by the designers, instructing where and how to move.

What are the different types of CNC machines?

Following are the different types of CNC machines:

- CNC Milling Machine:

CNC milling machines are perhaps the most recognizable type of CNC equipment. These machines use high-speed rotating cutting tools to remove material from a workpiece, shaping it to exact specifications. Available in both vertical and horizontal configurations, mills can utilize various cutting tools like end mills, reamers, face mills, taps, and drills.

Key Applications:

- Furniture manufacturing

- Prototype development

- Signage production

- Musical instrument creation

Limitations:

- Size constraints of the machine

- Requires skilled operators

- Higher initial investment costs

- CNC Router Machines:

CNC routers specialize in cutting intricate shapes on flat surfaces across different materials. They’ve effectively replaced multiple manual tools used in carpentry and metalworking, offering superior precision and repeatability.

Key Applications:

- Wooden furniture design

- Interior and exterior decorations

- Door carving

- Signage with complex designs

Challenges:

- High noise levels during operation

- Significant dust generation

- Material-specific limitations

- CNC Plasma Cutters

Plasma cutting machines use an electrical discharge arc to ionize air and melt materials, creating highly accurate cuts. This technique is exclusively applicable to electrically conductive materials.

Key Applications:

- Automotive manufacturing

- Automotive repair

- Metal fabrication

- Salvage and scrapping operations

Limitations:

- Only works with conductive materials

- Creates heat-affected zones during cutting

- CNC Lathes & Turning Machines

CNC lathes revolve the workpiece around a central axis while cutting tools shape the material. This technique is ideal for creating symmetrical components with exceptional speed and precision.

Key Applications:

- Automotive part manufacturing

- Camshaft production

- Musical instrument creation

- Furniture component design

Challenges:

- Limited to symmetrical component creation

- Higher operational complexity

- CNC Laser Cutting Machines

Laser cutters use highly focused laser beams to cut through various materials with extraordinary precision. Unlike plasma cutters, they aren’t limited to conductive materials.

Key Applications:

- Aerospace component manufacturing

- Medical equipment production

- Material engraving

- Intricate design cutting

Considerations:

- Limited material thickness capacity

- Requires highly skilled operators

- CNC Electrical Discharge Machines (EDM)

EDM uses electrical arcs to remove material, creating precise 2D cuts on metal sheets. This technique is particularly useful for complex geometries.

Key Applications:

- Injection mold manufacturing

- Die casting

- Prototyping

- Precision metal component creation

Limitations:

- Only works with conductive materials

- Slower cutting rates, especially for complex shapes

- CNC Waterjet Cutting Machine

Waterjet CNC machines use ultra-thin water jets to cut through virtually any material. Multi-axis waterjet cutters can even perform 3D cuts.

Key Applications:

- Stone and ceramic cutting

- Aerospace manufacturing

- Automotive design

- General fabrication

Challenges:

- Slower cutting speed

- Potential component breakdown with low-quality systems

- CNC Grinding Machines

CNC grinders use rotating ceramic-blend or diamond grinding wheels to remove material for finishing, polishing, and smoothing surfaces.

Key Applications:

- High-precision gear manufacturing

- Automotive parts

- Medical equipment production

- Aerospace components

Limitations:

- Extremely slow material removal process

- Primarily used for surface finishing

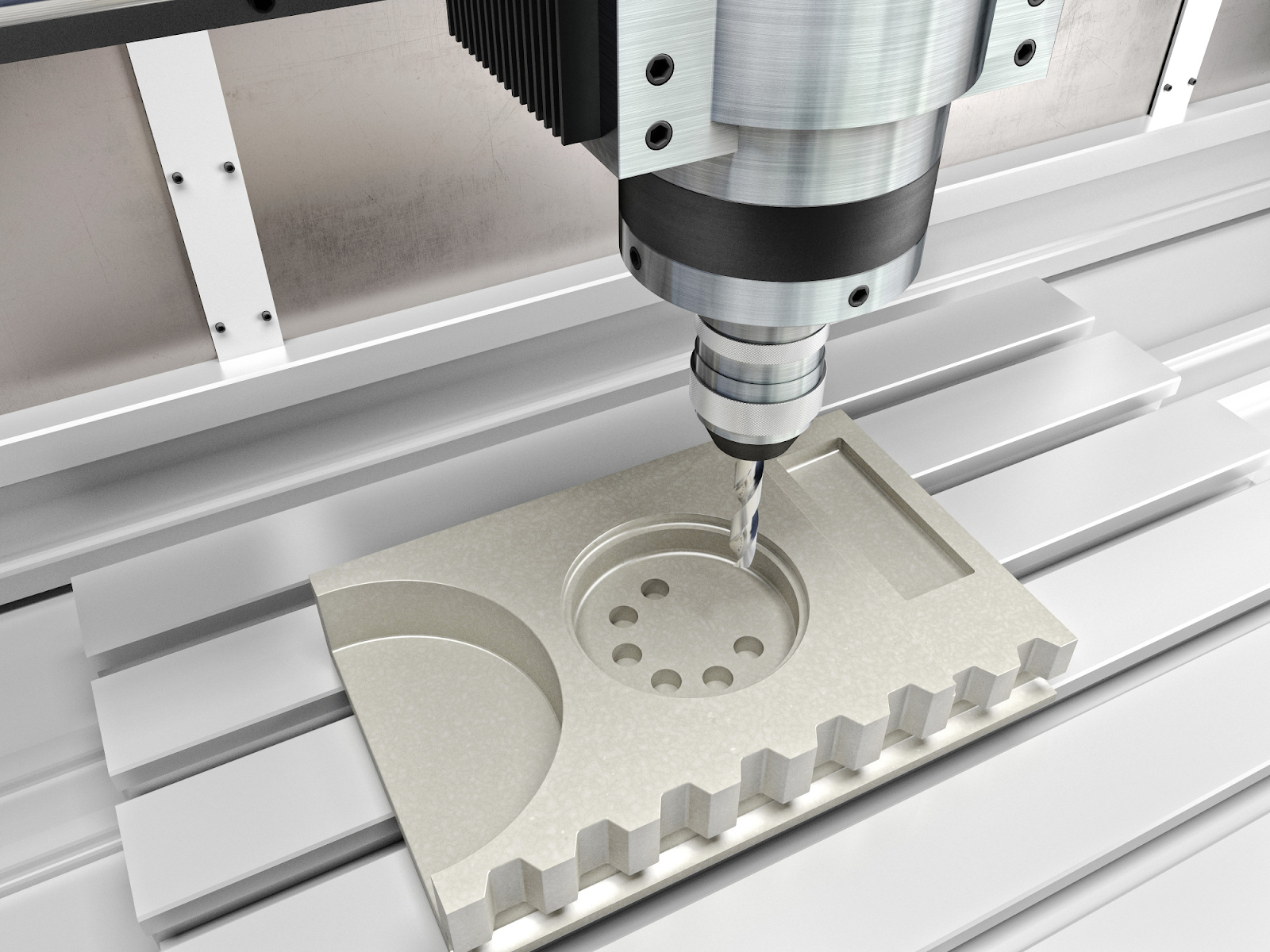

- CNC Drilling Machines

CNC drilling is a fundamental machining process focused on creating precise holes in various materials for assembly, aesthetic, or functional purposes.

Key Applications:

- Automotive manufacturing

- Shipbuilding

- Astronautics

- Mold making

- Furniture manufacturing

Considerations:

- Limited hole dimensions

- Requires specific drill bit sizes

- Multi-Axis Machining: Complex Geometries

From 2-axis to advanced 12-axis systems, multi-axis machining enables increasingly complex part creation with extraordinary precision.

Axis Progression:

- 2-Axis: Basic straight-line cuts

- 3-Axis: Standard machining

- 5-Axis: Simultaneous surface processing

- 9-Axis: Combined milling and lathe capabilities

- 12-Axis: Ultimate precision and speed

Conclusion

CNC machining continues to push the boundaries of innovation in manufacturing. As we progress more, we can expect even more precise, efficient, and versatile machining techniques.

Whether you’re looking to prototype a new product, manufacture complex components, or optimize production processes, Machine Maze has got you covered. We have a vetted supplier network who have attained all the industry certifications and they fulfill all the above-mentioned factors.

Gain access to instant quotes in 24 hours from our network in India and streamline your sourcing process with us.