Contract Manufacturing is a business model where the hiring company outsources the manufacturing of its components and products to a specialized manufacturing partner.

The following guide will help you understand the basics of contract manufacturing, the process, and how it helps modern businesses.

What is Contract Manufacturing?

Contract manufacturing, also known as Outsourced Manufacturing is where a company hires another company to undertake its production process. In this regard, the contract manufacturer agrees to manufacture products based on specifications provided by the hiring firm and also guarantees the quality and production at par.

The Contract Manufacturing Process

When a company engages in contract manufacturing, several key steps occur:

- Initial Agreement

- The hiring company shares product specifications

- Both parties negotiate terms and pricing

- Quality standards are established

- Legal agreements are finalized

- Trial Production

- Contract manufacturer creates initial samples

- Quality testing and verification

- Adjustments are made based on the feedback

- Mass Production

- Full-scale manufacturing begins

- Regular quality control checks

- Ongoing communication between the parties

Types of Contract Manufacturing Arrangements

- Component Manufacturing

- In this arrangement, a contract manufacturer develops parts or components that are used by the hiring company in one of its products. This setup is most commonly found in the manufacturing industries, especially in the fields of automobile and electronics.

- Individual Label Manufacturing

- The product is designed and produced by the contract manufacturer while the hiring company sells under its brand. Examples include consumer goods and supplements.

- Labor-Only Manufacturing

- The hiring company provides the materials while the contract manufacturer supplies the labor and allows the use of their facilities.

- Full-Service Production

- Here, the contract manufacturer controls the whole process of production, from design through packaging.

Advantages of Contract Manufacturing

There are numerous benefits of contract manufacturing, such as-

- Cost Effectiveness

- Concentration on Core Competencies

- Access to Expertise

- Flexibility

How to Select the Right Contract Manufacturer?

Following are the key points to consider when you are selecting the right contract manufacturer:

- Technical Capabilities

- Manufacturing experience

- Equipment and facility

- Quality control processes

- Production capacity

- Reputation and Experience

- History in the business

- Industry references

- Previous customer reviews

- Years of activity

- Location and Logistics

- Geographical proximity

- Shipping Capabilities

- Communication infrastructure

- Time zone

- Quality Certifications

- ISO certifications

- Industry-specific measures

- Quality management systems

- Regulatory compliance

Examples of Contract Manufacturing

Contract manufacturing is used in various ways by different industries:

- Electronics Industry

- Circuit board manufacturing

- Component manufacturing

- Device manufacturing

- Testing and quality control

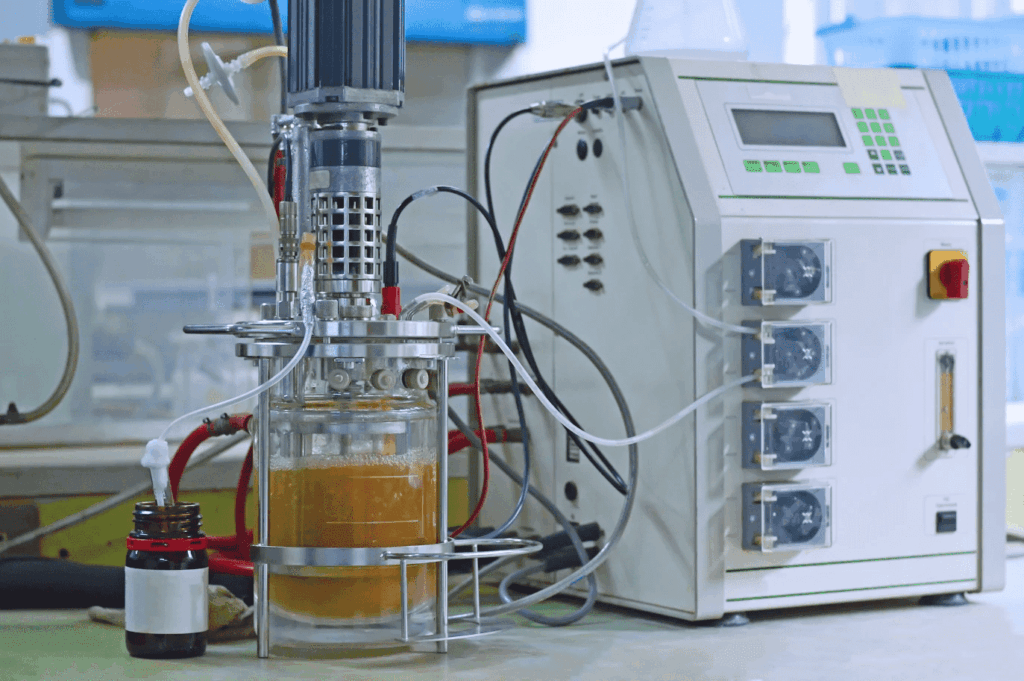

- Pharmaceutical Industry

- Drug manufacturing

- Packaging services

- Raw material processing

- Quality testing

- Automotive Sector

- Parts manufacturing

- Component assembly

- Testing and validation

- Supply chain management

Some Essential Agreements of Contract Manufacturing

- Manufacturing Agreement

- Manufacturing requirements

- Product quality standards

- Delivery conditions

- Price structure

- NDA

- Non-disclosure terms

- Protection of intellectual property

- Trade secret protection

- Usage Restrictions

Conclusion

The strategic practice of contract manufacturing can help enterprises find an innovative way of doing business in the modern competitive scenario. Moreover, if implemented correctly, it offers immense benefits for cost reduction, operational effectiveness, and market agility.

Key points that companies should remember:

- Key Takeaways:

- Contract manufacturing allows a firm to utilize expertise and other resources without heavy investment in capital.

- Success largely depends on the choice of the right contract manufacturer and the establishment of an agreement.

- The relationship thus calls for effective management in terms of quality standards, communication, and protection of intellectual property.

- It is highly flexible and can be modified according to the industries/situations.

For a company wanting to try out contract manufacturing, the following steps are important:

- Thorough assessment of the potential partner

- Legal agreements that include almost everything

- Good communication

- Good quality control

- Evaluation of the partnership for continuous improvement

We perform all of the above steps for our clients to make the process smooth. Connect with us to gain access to a certified network of suppliers, who will make your contract manufacturing process simple.