Digital technology is changing how we manufacture aircraft parts. For companies in the aerospace parts manufacturing industry, this means new ways to work better and faster. Let’s explore how these changes are creating new opportunities.

How Digital Technology is Changing Manufacturing?

The aerospace and defense electronic manufacturing services market is growing quickly. New digital tools are helping companies work more efficiently. For aerospace parts suppliers and manufacturers, these changes bring many benefits.

Digital Copies of Parts

Companies now make digital copies of real parts. These help aerospace components manufacturers test how parts would work without building them. Through these digital copies, manufacturers can find problems before they happen, while making better designs more quickly. This approach helps save both money and time in the development process.

Smart Manufacturing Tools

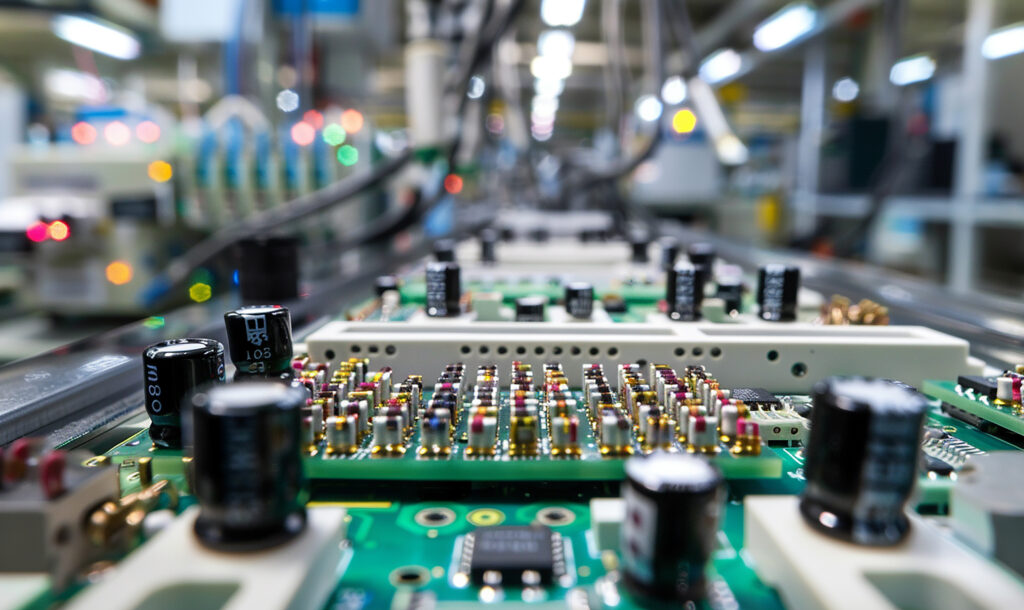

Aerospace parts manufacturers are revolutionizing their operations through smart tools. Advanced robots are transforming production by building complex parts with precision, executing the same task perfectly every time, and significantly reducing mistakes.

Connected sensors have become integral to modern manufacturing, enabling real-time production monitoring, proactive problem resolution, and enhanced quality control. Smart computer systems optimize operations by improving production planning, quickly identifying defects, and efficiently managing supplies.

Better Supply Management

For aerospace parts suppliers, digital tools improve how they manage parts:

Better Tracking

The implementation of advanced tracking systems allows companies to maintain constant awareness of part locations, implement better stock control measures, and accurately plan for future needs based on real-time data.

Digital Supply Chain Innovation

Modern supply chains leverage blockchain technology to track parts throughout their journey. Secure digital platforms facilitate seamless supplier connections, while real-time updates keep all partners informed. Automated ordering systems minimize delays, and artificial intelligence capabilities help predict supply needs with remarkable accuracy.

Environmental Benefits

Companies can reduce paper waste through digital documentation, lower their carbon footprint with optimized shipping routes, and track and reduce energy usage in manufacturing. This digital transformation allows better monitoring and decrease of material waste while supporting sustainable manufacturing practices. The result is faster work processes – ordering parts more easily, getting them faster, and moving them more efficiently.

Benefits for Aerospace Components Suppliers

Save Money

- Use less material

- Use resources better

- Reduce stopped production

Better Quality

- Make parts the same way every time

- Follow the rules better

- Make more reliable parts

Create New Things Faster

- Test new designs quickly

- Make changes easily

- Get new parts to market faster

Digital Collaboration Benefits

- Work with teams across different locations

- Share designs and updates instantly

- Solve problems faster through online meetings

- Keep all project information in one place

- Track progress across multiple facilities

Market Advantages

- Respond to customer needs faster

- Adjust production quickly to market changes

- Find new business opportunities through data analysis

- Build stronger relationships with digital communication

- Stay ahead of industry trends

Problems and Solutions

Digital changes bring challenges, such as:

Cost

- Solution: Make changes step by step

- Plan to spend carefully

- Start with the most important changes

Training Needs

- Solution: Train workers well

- Work with technology experts

- Keep learning new things

Keeping Information Safe

- Solution: Use strong security

- Check security regularly

- Share information safely

How Does Machine Maze Help?

Machine Maze helps aerospace parts manufacturers use digital tools better. We connect companies with trusted manufacturers in India through our online platform.

Machine Maze stands at the forefront of this digital revolution, helping aerospace parts manufacturers use digital tools better. Through our online platform, we connect companies with trusted manufacturers in India. Our solution is designed for ease of use, allowing businesses to work with trusted Indian manufacturers, watch production happening in real-time, and check quality easily. The platform provides complete visibility, enabling companies to track work as it happens.

Future Changes

The aerospace parts manufacturing industry keeps improving with new technology:

3D Printing

- Make complex parts

- Waste less material

- Test designs faster

Special Viewing Tools

- Help build parts better

- Make repairs easier

- Train workers better

Secure Record-Keeping

- Track parts safely

- Know where parts come from

- Follow the rules better

Start Now

Ready to improve your manufacturing? Machine Maze can help. Our platform gives you:

- Clear processes

- Watch production happening

- Quality checking

- Ways to grow

Don’t fall behind.

Contact Machine Maze today to see how we can help you.

MACHINE MAZE

info@machinemaze.com

+91 96068 02433