The European electric vehicle market stands in a critical position. With the EU’s ambitious target to phase out ICE vehicles by 2035, EV manufacturers face unexpected opportunities and significant challenges. Let’s examine the current state of EV manufacturing in Europe and explore practical solutions for manufacturers and suppliers.

The Current State of European EV Manufacturing

The EV market in Europe has grown significantly, with market share exceeding 20% of new vehicle sales. However, this growth hides the underlying challenges in the manufacturing ecosystem. European OEMs currently capture only 70-75% of the value added in domestically produced EVs, compared to 85-90% for traditional ICE vehicles. This gap represents a crucial challenge for the industry’s future profitability and sustainability.

Core Manufacturing Challenges

1. Battery Supply Chain Dependencies:

The most concerning challenge facing European EV manufacturers is the battery supply chain. With over €40 billion in battery imports in 2022 (€17.6 billion from China alone), Europe’s dependency on Asian EV battery suppliers creates significant vulnerabilities. Critical materials like lithium, primarily sourced from Australia, Chile, and China, further complicate the supply chain landscape.

2. Component Manufacturing Gaps:

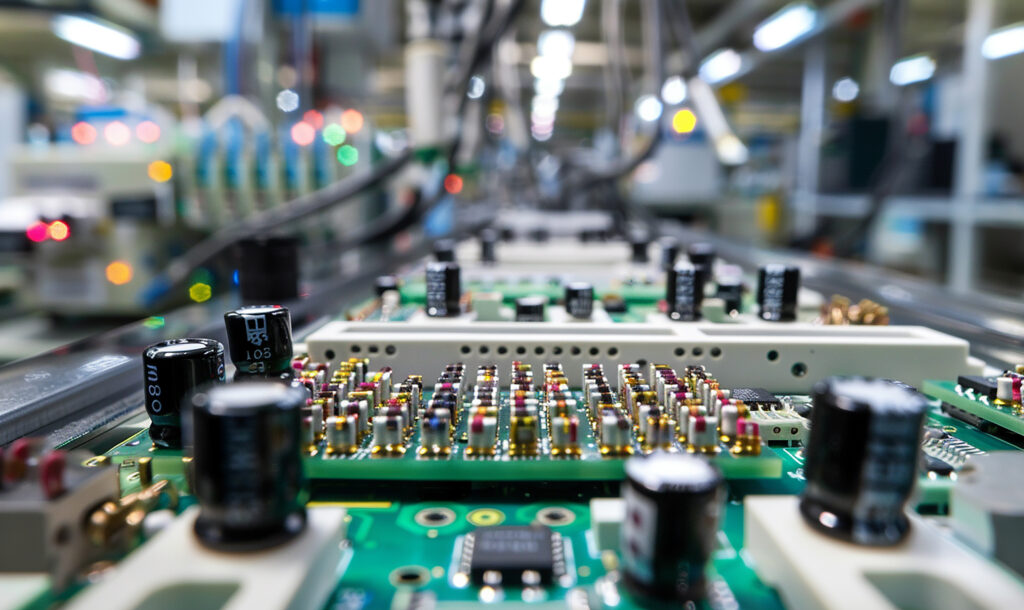

Beyond batteries, EV component manufacturers struggle with securing reliable supplies of:

- Electric motors and powertrains

- Power Electronics

- Charging systems

- Advanced thermal management components

( Check Detailed Article on How To Choose The Best Auto-Component Manufacturers? )

3. Cost Competitiveness:

European manufacturers face a significant cost disadvantage compared to Asian competitors, who can produce EVs 20-30% cheaper while achieving twice the development speed. High energy costs in Europe (2-3 times higher than in the US and China) further reduces the competitiveness.

Strategic Solutions for Manufacturers

1. Supply Chain Diversification:

While Europe builds its battery manufacturing capacity (35 new gigafactories planned by 2035), manufacturers need immediate solutions. This is where strategic partnerships with established EV part suppliers in countries like India become crucial.

2. Component Sourcing Strategy:

Developing a robust component sourcing strategy requires the following:

- Multiple supplier relationships across different regions

- Local manufacturing partnerships in cost-competitive countries

- Investment in supply chain visibility and management systems

- Strong quality control processes

3. Manufacturing Innovation:

To remain competitive, European manufacturers need to focus on:

- Automation and Industry 4.0 implementation

- Advanced manufacturing processes

- Modular production systems

- Lean manufacturing principles

The India Advantage

Electric vehicle part manufacturing in India has emerged as a promising partner for European EV manufacturers, offering:

- Skilled engineering talent

- Cost-competitive manufacturing

- Growing EV component manufacturing ecosystem

- Strong quality management systems

- Established automotive manufacturing infrastructure

However, finding and managing reliable manufacturing partners in India has traditionally been challenging for European companies.

Bridging the Gap with Machine Maze

This is where Machine Maze comes in as a game-changing solution. Our platform connects European OEMs with vetted Indian manufacturing partners through advanced cloud-based Manufacturing as a Service (MaaS) technology.

We offer:

- Access to pre-verified, high-quality Indian manufacturing partners

- Real-time visibility across the manufacturing process

- Secure and transparent communication channels

- Quality control and compliance monitoring

- Seamless scaling capabilities

Emerging Trends in Indian Manufacturing Capabilities

The Indian manufacturing sector is rapidly evolving to meet global EV demands:

- Development of specialized EV manufacturing clusters

- Investment in advanced battery technology research

- Growing expertise in power electronics

- Establishment of testing and validation facilities

- Innovation in lightweight materials and components

Future Outlook

The success of the European EV manufacturing sector will depend on- building robust supply chain partnerships, leveraging cost-competitive manufacturing locations, implementing advanced manufacturing technologies, and ensuring quality and compliance across the supply chain.

For manufacturers looking to strengthen their position in the EV market in Europe, now is the time to act. Building strong partnerships with reliable manufacturing partners in countries like India can provide the competitive edge needed to succeed in this rapidly evolving market.

Machine Maze’s Success Stories

Leading European manufacturers have already benefited from our platform:

- Reduced component sourcing time by 60%

- Achieved 25% cost savings through optimized partner selection

- Improved production quality with real-time monitoring

- Accelerated time-to-market for new EV models

- Enhanced supply chain resilience through diversification

What’s there for you?

- Connect with qualified Indian manufacturing partners

- Streamline your supply chain

- Reduce manufacturing costs

- Maintain quality and compliance

- Scale your production efficiently

Visit Machine Maze today to learn how we can help you navigate the challenges of EV manufacturing and build a more resilient supply chain.

Contact our team for a personalized consultation and discover how our platform can transform your manufacturing operations.

Check Machine Maze’s Electric Vehicle Component Manufacturing Capabilities

Check Machine Maze’s Electric Vehicle Component Manufacturing Capabilities