ABS

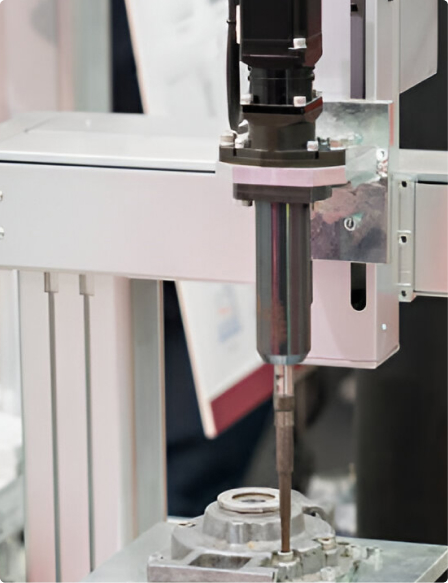

ABS (Acrylonitrile Butadiene Styrene) is a high-performance thermoplastic well known for its impact resistance, toughness, and dimensional stability. Its ability to withstand extreme temperatures makes it suitable for precision-machined parts in various applications, such as automotive components, electronic housings, and mechanical parts. Machine Maze's skilled technicians possess the expertise to machine ABS with precision and reliability, ensuring that businesses receive components that surpass their expectations.