India’s aerospace industry has been making remarkable success in recent years, positioning itself as a global leader in aircraft manufacturing. The country’s innovative companies are not just producing aircraft but are revolutionizing the entire aerospace ecosystem.

Leaders Shaping India’s Aerospace Future

The Indian aerospace manufacturing sector represents an ecosystem of public and private entities working collaboratively to push technological boundaries. These companies are driven by a combination of national strategic interests, technological ambition, and a commitment to global excellence.

1. Hindustan Aeronautics Limited (HAL): The Pioneering Giant

The Pioneering Giant, HAL, stands as a testament to India’s aerospace capabilities. With over seven decades of experience, this company has been the backbone of India’s aircraft manufacturing prowess. Their approach to aerospace manufacturing is characterized by the following:

- Indigenous production of the Tejas Light Combat Aircraft (LCA)

- Development of the Advanced Light Helicopter (ALH)

- Comprehensive expertise in aircraft upgrades and critical component manufacturing

- A rich history of contributing to India’s defense and aerospace capabilities

The company’s journey reflects India’s technological evolution, transforming from a nascent aerospace player to a respected global manufacturer. On January 3, 2016, a milestone ceremony in Tumakuru near Bengaluru marked the launch of a new facility for producing domestic Light Utility Helicopters (LUH).

2. Tata Advanced Systems Limited (TASL): Private Sector Innovation

As a subsidiary of the legendary Tata Sons, TASL represents the perfect combination of innovation and strategic partnerships. Their approach to aerospace manufacturing is characterized by the following:

- State-of-the-art manufacturing facilities

- Strategic global partnerships with leading aerospace OEMs

- Successful delivery of critical aerospace components

- Expertise in manufacturing fuselages, wings, and advanced avionics systems

TASL demonstrates how the dynamic nature of the private sector can drive aerospace innovation in India.

3. Mahindra Aerospace: Versatility and Global Recognition

The Mahindra Group’s aerospace division has quickly established itself as a key player. Their distinctive features include:

- Production of the internationally acclaimed Airvan series of utility aircraft

- Focus on advanced manufacturing techniques

- Commitment to quality and global standards

- Design and development of diverse aircraft components

Mahindra Aerospace showcases how Indian companies can create cost-effective, versatile airplane manufacturing solutions.

4. Aeronautical Development Agency (ADA): Technology Trailblazers

ADA plays a crucial role in pushing the boundaries of aerospace technology. Their key contributions include:

- Spearheading the development of the Tejas Light Combat Aircraft

- Collaborating with multiple aerospace organizations

- Driving the design and development of advanced fighter aircraft

- Showcasing India’s capabilities in cutting-edge aerospace technology

5. Dynamatic Technologies Limited: Precision Engineering

Specializing in precision engineering, Dynamatic Technologies has made a niche in the aerospace manufacturing landscape:

- Expertise in complex aerostructures and hydraulics

- Supplying critical components to global aerospace programs

- Commitment to continuous research and development

- Strong focus on innovation and global partnerships

Conclusion

While these aircraft companies in India are pushing aerospace boundaries, Machine Maze is known for providing critical support to the industry’s growth. The company has comprehensive manufacturing capabilities that can help aerospace manufacturing companies streamline their production processes.

How Does Machine Maze Support Aerospace Manufacturing?

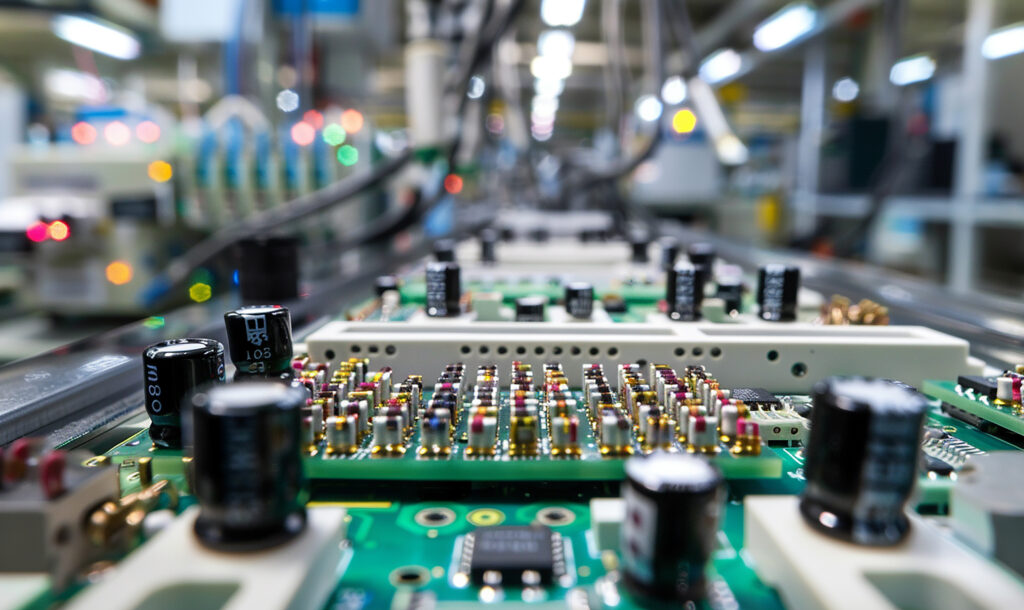

- Precision machining capabilities

- Advanced casting technologies

- Comprehensive assembly solutions

- Electronic manufacturing services

- Serving industries including aerospace and defense

Connect with Machine Maze and unlock your manufacturing potential.

Frequently Asked Questions

Q1: What makes India an emerging player in aerospace manufacturing?

A: India has developed a robust aerospace ecosystem through significant government investments, advanced technological capabilities, strong engineering talent, strategic partnerships with global aerospace companies, and commitment to indigenous manufacturing technologies.

Q2: How do Indian aircraft manufacturers compete globally?

A: Indian aerospace companies compete through cost-effective manufacturing solutions, high-quality precision engineering, innovative design capabilities, advanced technological expertise, and the ability to produce complex aerospace components at competitive prices.

Q3: What are the key challenges in Indian aerospace manufacturing?

A: Primary challenges in Indian aerospace manufacturing include high initial infrastructure investments, complex technological requirements, the need for continuous skill upgradation, stringent global quality standards, and intense international competition.

Q4: How is the Indian government supporting aerospace manufacturing?

A: By implementing favorable policy frameworks, the government creates an enabling environment for aerospace industrial development. To accelerate sector growth, the government is actively encouraging private sector participation, recognizing the crucial role of industry players in driving technological progress.

Q5: What future technologies are Indian aerospace companies exploring?

A: The key focus is on advanced composite materials that offer superior strength-to-weight ratios, enabling more efficient and high-performance aircraft design. Electric and hybrid aircraft technologies are receiving significant attention, reflecting a global shift towards sustainable and environmentally friendly aviation solutions.

Q6: How do Indian aircraft manufacturers ensure quality and safety?

A: Indian aircraft manufacturers are implementing comprehensive and rigorous quality assurance mechanisms to meet and exceed global aerospace standards. Obtaining and maintaining rigorous international certifications is a fundamental aspect of their quality management approach, ensuring compliance with the most demanding global benchmarks.