In the contract manufacturing business model, a hiring company outsources a component development to a third party, based on their skills, experience, and expertise.

In this blog, we will explore 10 benefits of contract manufacturing and how it can transform business operations.

Advantages of contract manufacturing

Following are the major 10 benefits of contract manufacturing:

- Significant cost reduction:

The biggest contract manufacturing benefit is cost savings. Outsourcing to a third party enables businesses to:

- Eliminate the need for expensive equipment

- Reduce the overhead costs associated with maintaining the production facilities

- Minimize the labor and training costs

- Convert fixed costs into variable costs, thus improving the financial stability

- Improved product quality:

Contract manufacturers focus on providing:

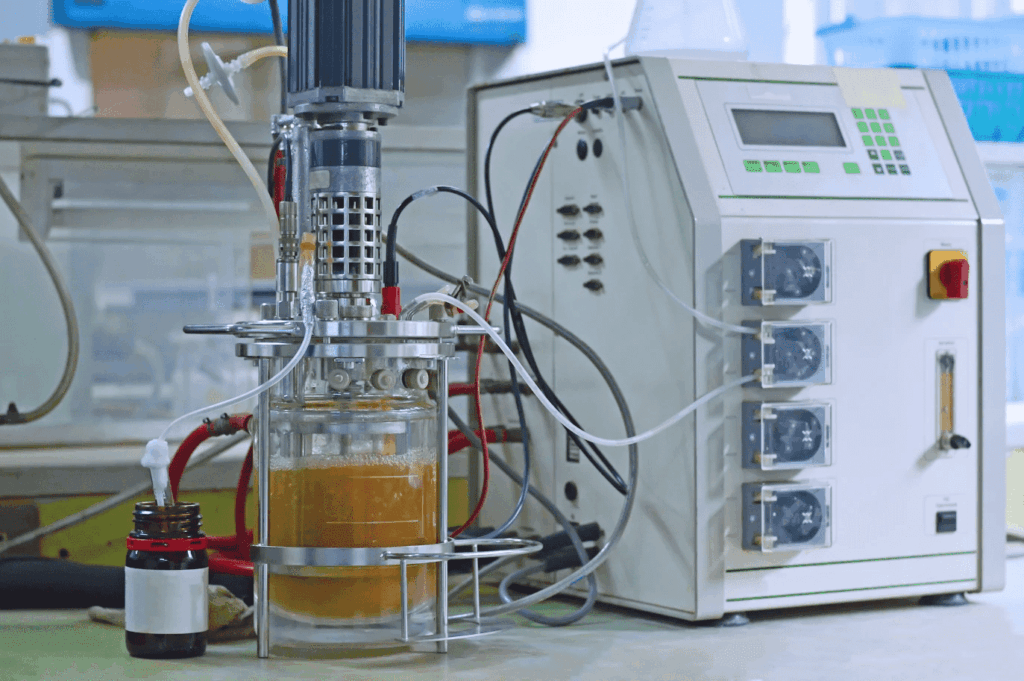

- State-of-the-art technological skills

- Modern equipment and facilities

- Strict quality control standards

- Compliance with industry standards and regulations

- Continuous improvement of manufacturing processes

- Reduction in time to market the product

Speed is an essential component in business. Contract manufacturing offers:

- On-demand access to manufacturing capacity

- Reduced setup time

- Smoothened production processes

- Efficient scaling of production

- Quick response to market demands

- Specialized Expertise

A significant benefit of contract manufacturing is access to specialty knowledge, in the form of:

- Industry-specific manufacturing experience

- Technical innovation and process improvement

- Advanced equipment operation

- Regulatory compliance knowledge.

- Problem-solving abilities

- Access to flexibility:

Contract manufacturing provides flexibility by:

- Allowing rapid scaling of production up or down

- Adapting easily to seasonal demands

- Mitigating risk due to market fluctuations

- Reducing commitments tied up in fixed assets

- Extending geographic reach

- Focus on core competencies:

Third party manufacturing enables companies to:

- Concentrate on product development

- Enhance marketing and sales efforts

- Build stronger customer relationships

- Invest more in research and development

- Improve overall business strategy performance

- Optimization of value chains:

The advantages of third-party manufacturing extend to supply chain management, in the form of:

- Less burden in inventory management

- Smoother material sourcing processes

- Stronger supplier relationships

- Better logistics management

- Greater supply chain visibility

- Risk management:

Contract manufacturing reduces a variety of business risks:

- Lowered capital investment risk

- Shared responsibility in regulatory compliance

- Fewer equipment maintenance concerns

- Reduced exposure to manufacturing-related issues

- Smarter management of market uncertainties

- Entry into the global market:

Contract manufacturers provide:

- International manufacturing capacity

- Local market knowledge

- Established distribution networks

- Compliance with international standards

- Cultural and linguistic competence

- Technological development:

Staying current with manufacturing technology is easier with contract manufacturing, allowing:

- Access to the latest machinery

- Advanced production techniques

- Improved quality control systems

- Modern inventory management systems

- Cutting-edge process automation

Maximizing Value with Contract Manufacturing

To maximize the benefits of contract manufacturing, consider these best practices:

- Careful choice of partners

- Screen potential manufacturers thoroughly

- Check references and track records

- Assess financial stability

- Review quality certifications

- Analyze technical capabilities

- Clear Communication

- Establish detailed specifications

- Set clear expectations

- Maintain regular communication

- Define quality standards

- Document all agreements

- Quality Control

- Implement quality monitoring systems

- Conduct routine audits

- Define acceptance criteria

- Set up feedback mechanisms

- Track performance metrics

Conclusion

In a nutshell, contract manufacturing is a powerful instrument for any company, if it needs to improve its functioning or wants to grow. It offers clear benefits, such as lower costs, enhanced quality, flexibility, and focus on the competitive scope. If these benefits of contract manufacturing are managed and developed properly by choosing the right partners and maintaining the proper relations with them, all these can turn into factors improving the stability and increasing the competitive advantage.

We, at Machine Maze ensure that our clients experience all the benefits of contract manufacturing through our supplier network in India.

From a startup company just waiting to bring its first product to market to a mature organization that is now seeking to optimize its manufacturing processes, contract manufacturing provides the resources and expertise necessary to achieve success in today’s marketplace.