In today’s global marketplace, Original Equipment Manufacturers (OEMs) play a key role in product creation, assembly, and market delivery. But what exactly does this term mean, and why is it so important in modern manufacturing?

Let’s dive deep into understanding “what an OEM manufacturer is” and how they shape the products we use daily.

Understanding The Basics Of OEM

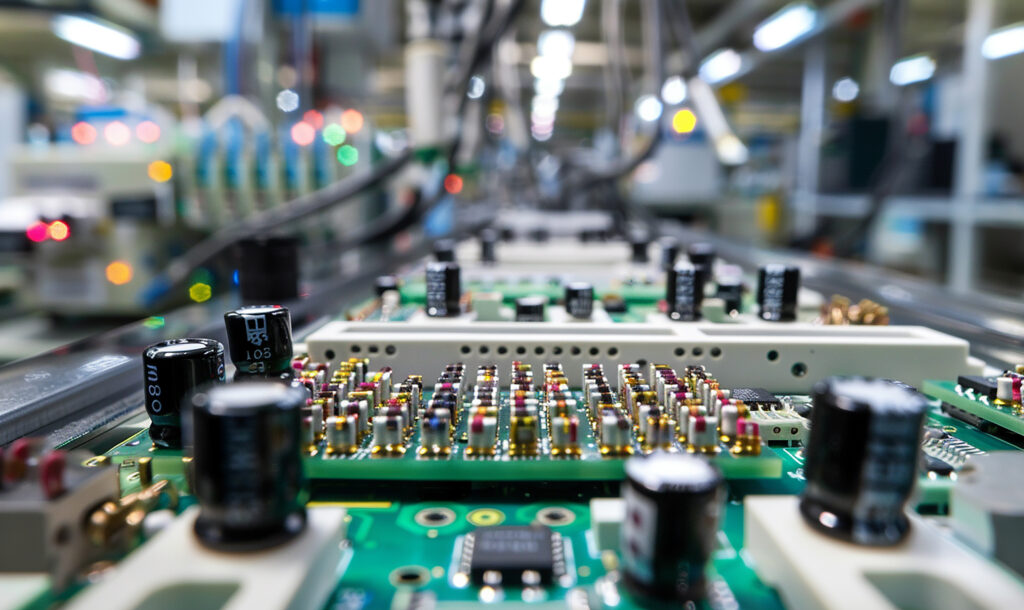

At its core, an “Original Equipment Manufacturer” is a company that produces parts, components, or equipment that are used in another company’s end products. Think of OEMs as behind-the-scenes creators of essential components that power the products you use.

Consider your smartphone, for instance. While it might bear the logo of a well-known brand like Apple or Samsung, many of its components – from the camera sensors to the display panels – are manufactured by different OEMs. These companies specialize in creating specific parts that meet the exact specifications provided by the final product manufacturer.

The Business Model: How OEMs Operate

What are OEM companies and how do they function in the broader manufacturing ecosystem?

OEMs typically operate on a business-to-business (B2B) model, working closely with what are known as Value-Added Resellers (VARs). When someone asks what you mean by OEM products, it’s important to understand this relationship.

The OEM creates specialized components or products based on the VAR’s specifications. The VAR then incorporates these components into their final products, adds their branding, and sells them to end consumers. This relationship allows both parties to focus on their core competencies – the OEM on manufacturing excellence and the VAR on product design, marketing, and distribution.

The Transformation of OEM Relationships

The concept of what an OEM supplier is has evolved significantly over the years. Initially, OEMs were simply component manufacturers, but today, many have expanded their roles to become full-service partners in the product development process. Modern OEMs often provide:

1. Design and engineering expertise

2. Quality control and testing services

3. Supply chain management

4. After-sales support and warranty services

This change has made understanding original equipment manufacturers more complex, as their roles continue to expand and adapt to market needs.

The OEM Ecosystem: A Deeper Look

Supply Chain Integration

Understanding what OEM is requires examining how these manufacturers fit into the broader supply chain. OEMs often serve as important middle links in complex supply chains, working with raw material suppliers upstream while coordinating with VARs downstream. This position requires sophisticated logistics management and careful quality control at every step.

Quality Control and Standards

Quality standards are always paramount. OEMs must adhere to various international standards and certifications, depending on their industry and target market. These might include:

– ISO certifications for quality management

– Industry-specific standards (such as automotive or aerospace requirements)

– Regional compliance requirements

– Environmental and sustainability standards

Global Market Dynamics

The global nature of modern manufacturing has transformed how OEMs operate. Today, what an original equipment manufacturer does often spans multiple countries and continents. This global reach brings both opportunities and challenges:

Opportunities:

– Access to diverse markets and resources

– Ability to optimize production costs

– Greater innovation potential through international collaboration

Challenges:

– Complex supply chain management

– Cultural and communication barriers

– Varying regulatory requirements

– Currency fluctuations and trade policies

Industry-Specific OEM Applications

Automotive Sector

The automotive industry provides one of the clearest examples of how OEMs operate. Think about the thousands of parts that go into making a single car. From brake systems to electronic components, numerous OEMs supply parts that automakers then assemble into the final vehicle.

Emerging Trends in Automotive OEM:

– Advanced driver-assistance systems (ADAS)

– Connected car technologies

– Lightweight materials and composites

Technology and Electronics

In the tech sector, what OEM is takes on a slightly different meaning. Here, OEMs might provide not just hardware components but also software solutions. Microsoft, for instance, acts as an OEM when it supplies its Windows operating system to computer manufacturers.

Healthcare and Medical Devices

The healthcare sector represents a growing market for OEMs, with strict requirements for:

– Precision manufacturing

– Sterility and biocompatibility

– Regulatory compliance

– Documentation and traceability

The Digital Transformation of OEMs

Industry 4.0 Integration

Modern OEMs are adopting Industry 4.0 technologies, revolutionizing their products through smart manufacturing, IoT integration, AI, machine learning, predictive maintenance, and digital twin technology.

Data-Driven Manufacturing

Understanding what is an OEM in the digital age means recognizing the importance of data analytics in:

– Quality control

– Process optimization

– Inventory management

– Predictive maintenance

– Customer relationship management

Sustainability and Environmental Responsibility

Green Manufacturing Practices

Modern OEMs are increasingly focused on sustainable practices, including:

– Renewable energy usage

– Waste reduction and recycling

– Sustainable material sourcing

– Carbon footprint reduction

– Water conservation

Circular Economy Integration

This concept now includes responsibility for product lifecycle management:

– Design for recyclability

– Remanufacturing programs

– End-of-life product management

– Resource recovery systems

Future Trends and Innovations

Emerging Technologies

The future of OEMs will be shaped by 3D printing, blockchain, advanced robotics, quantum computing, and augmented reality in manufacturing.

Market Evolution

OEM roles are evolving to include greater customization, direct-to-consumer channels, service models, digital marketplaces, and advanced collaboration platforms.

Conclusion

Understanding what an OEM manufacturer is crucial in today’s manufacturing industry. These companies play an important role in creating the products we use daily, even though their contributions often go unnoticed by end consumers. As manufacturing continues to transform, the importance of OEMs in global supply chains will only grow, making their role even more crucial in shaping the future of product development and manufacturing.

The future of OEM manufacturing lies in adaptation and innovation. As technology advances and market demands shift, successful OEMs will be those that can balance traditional manufacturing excellence with modern digital capabilities, sustainable practices, and agile business models. Whether you’re a business leader considering OEM partnerships or simply curious about how products are made, understanding the role of original equipment manufacturers provides valuable insight into modern manufacturing and product development.

This comprehensive understanding of OEMs reveals not just their current importance but also their potential to shape the future of global manufacturing and commerce. As we move forward, these partnerships will continue to drive innovation and efficiency across industries, ultimately delivering better products and services to end consumers while maintaining sustainable and responsible manufacturing practices.